THE OLIVER CORPORATION

In June 1857, James Oliver received his first patent, Number 76,939.1 It covered the essential features of the chilled iron plow and in February of the following year, he was granted another patent that covered the unique chilling process, which Mr. Oliver had developed.2 By 1868 the small Oliver factory was incorporated and renamed as the South Bend Iron Works. The stockholders of this newly formed company included George Milburn (of the Milburn Wagon Company, Mishawaka, Indiana), his son-in-law Clement Studebaker (of the Studebaker Manufacturing Company), and a few other important businessmen of South Bend.

The South Bend Iron Works built a new foundry, warehouse, machine shop, and a wood shop. The factory, in addition to making plows, kept busy by making castings for Singer Sewing Machine Company, casting wagon skeins for Studebaker, and making numerous other castings on order. Oliver continued making wagon skeins for Studebaker until 1874, by which time the volume of plow orders had grown so much that Oliver then devoted full time to making the Oliver Chilled Plow.

In 1870 the Oliver trademark was adopted and would, from then on, appear on every Oliver Chilled Plow produced. The South Bend Register commented in 1871 that Oliver “…[if he keeps on improving his plow] it will soon have no rivals in the country. The popularity of the Oliver Chilled Plow is almost unprecedented in the history of plows.”3 In 1871 the factory sold 1,500 plows, three years later the company made and sold 17,000 plows and had outgrown their factory. In 1874 Mr. Oliver bought about 40 acres of property in the southwest portion of South Bend (the property started at the northwest corner of Sample and Chapin Streets).4 Not only did the factory increase in size, the Oliver product line began to increase as well. Clement Studebaker thought Mr. Oliver was spending too much money and sold his shares back to the Oliver family. The Oliver family now owned 1,713 of the original 2,000 shares the company issued. The Oliver company had 200 employees.

By 1877 the company had established branch houses (dealerships of Oliver equipment) in Mansfield, Ohio; Dallas, Texas; Rochester, New York; Harrisburg, Pennsylvania; and San Francisco, California. In 1879 the company began to export the Oliver plow to Scotland. Also, the plant expanded and railroad tracks were extended into the plant. By 1881 James Oliver had purchased the remaining stock, which made the company a completely family owned business. The plant was producing 600 plows per day and employed 900 people.

However, in 1885 there were problems. Labor strikes, riots, and disputes plagued the factory. On January 12, 1885 a great strike and riot started when men forcibly entered the Oliver plant and forced the employees to stop working. The next day at 7:00 a.m. 200 men armed with clubs and iron bars assembled at the front gates and refused admittance to the factory. There is a story that a South Bend resident by the name of Captain Nicar, an old Civil War veteran, forced his way into the office after receiving several wounds on his head and arms. Captain Nicar was forced to draw his revolver and held the mob at bay. A policeman that was answering Mr. Nicar’s call for help was severely beaten.5 The mob then entered the factory and 100 men went through the building breaking windows and plow bases. Nicar called in the veteran guard, which arrived with about 50 men (with fixed bayonets). The crowd was dispersed with no further bloodshed. Twelve deputy sheriffs were called in to protect the factory throughout the night. All firearms were removed from the local gun shops in South Bend and locked up in the South Bend Court House.6 Ten men were arrested on charges of riot, assault and battery.

The factory remained closed until March 3, 1885. James had seriously considered moving the plant and plow operations to another city, leaving South Bend altogether. On February 21, 1885 there was a mass meeting at the courthouse, called by the mayor, to try and persuade the Olivers to remain in South Bend. Resolutions were adopted and presented to the Olivers who relayed the pledges made would be considered.7 On March 3, 1885, James wrote in his journal, “have determined to start the factory tomorrow.”8 Several of the rioters that were arrested were fined $100 and given 30 to 60 days in jail.

In 1887 the Oliver company began exporting plows to South America, which resulted in thousands and thousands of Oliver plows sold that year. The plow market then expanded to include Africa, Australia, and France. The phrase “Plowmakers for the World” was adopted as a trademark of the Oliver plow.

In 1901 the South Bend Iron Works was incorporated and the name was changed to the Oliver Chilled Plow Works with all 5,000 company shares held by members of the Oliver family.9 By 1905, James Oliver had been in the plow business for 50 years. This was also the most productive and successful year for the Oliver Chilled Plow Works.

The following year, at the age of 83, James was granted the last of his 45 patents. He had been successful in making the plow a useful and strong farming instrument. In a U.S. Senate report to Congress it was stated that if, for a single year, all the farmers in the United States would use the Oliver Chilled Plow instead of regular steel or iron plows, the savings in labor would have totaled the sum of $45,000,000 (and this was the early 1900s)!10 In 1910 it required 135 man-hours to produce 100 bushels of corn. Through the innovations of James Oliver, that amount of time had decreased to 23 man-hours by 1960.11

In 1908 James Oliver died at the age of 85. His son, Joseph Doty Oliver (J.D.), replaced him as President and J.D.’s son, James II, became Director. The company was continuing to grow and by 1909 there were 2,600 employees working at the Oliver Chilled Plow Works in South Bend. More branch houses (dealerships) were established in St. Louis, Missouri; Memphis, Tennessee; Billings, Montana; and the expansion of a new plant in Hamilton, Ontario, Canada. From 1913 to 1914 sales began to drop and business was becoming slow. However, it was a temporary slow down, because business began to increase in the years leading up to 1918. Business had increased so much that the Oliver company built plant number two (a little south and west of plant #1) for the purpose of building tractor plows. Motorized, internal combustion engines were now becoming accessible to the general farmer.

The Oliver Chilled Plow Works had been the sole producer of tractor plows for Henry Ford’s tractor (the Fordson). However, Henry Ford was beginning to show more interest in his automobile business than tractor production. J.D. realized that if Ford pulled out, they would lose a large portion of their business. The Oliver company started to experiment with the creation of a tractor of their own. The first tractor they produced was called the Oliver Chilled Plow Tractor. There were only about 20 manufactured and distributed throughout the United States, where it was well-received.12

J.D. was now getting older, but he still had the incredible ability to peer into the future of agriculture and farming. He knew that the Oliver Chilled Plow Works needed to offer a full-range of farming equipment to remain a competitive company. In order for this to happen, it would require a huge expansion and a lot of money and capital. The only option available to the Oliver company was to merge with other companies to make a full-line company. The result was the merger of four companies. These four companies were:

Hart-Parr Tractor Works

Nichols&Shepard Company

Oliver Chilled Plow Works

American Seeding Company

J.D. was named as the Chairman of the Board and his son, James II, became Vice-President. The assets of the Oliver Chilled Plow Works exceeded the combined assets of the other companies and J.D. was quoted as saying, “my name goes on the company, or the deal’s off.” Thus the Oliver Farm Equipment Company was the chosen name.13 Even though J.D. died in 1933, his legacy continued. Soon the Oliver Farm Equipment Company began adding to their line of machinery by acquiring additional plants. There were four plants established and each produced their own products. These plants were located in: South Bend, Indiana; Charles City, Iowa; Battle Creek, Michigan; and Springfield, Ohio. The following companies made up the Oliver Farm Equipment Company:

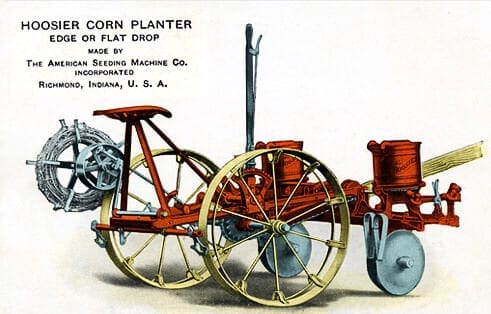

American Seeding Company

The Hoosier Drill Company was started by Joseph Ingels in 1857 and operated at Milton, Indiana. The company was acquired by American Seeding Machine Company in 1868 when the company was reorganized as the Hoosier Drill Company. They manufactured, at first, corn planting drills (hollow spikes that ‘drilled’ into the ground and deposited a seed) and then broadcast seeders.

P.P. Mast and Company, of Springfield, Ohio was another member of the

Several other drill manufacturers made up the 1903 merger under American Seeding Machine Company. Superior Drill Company, Empire Drill Company, and Bickford & Huffman were also merged (with the previously mentioned companies) into the American Seeding Machine and lost their individual identities in the 1929 merger into the Oliver Farm Equipment Company.

Hart-Parr Company

Charles Walter Hart and Charles H. Parr met at the University of Wisconsin and became very close friends. Close to the end of their college career they decided to work cooperatively on a thesis that brought about the development of their first engine. Their thesis dealt with the limitations of early internal combustion engines and Hart-Parr developed an engine that eliminated those limitations (or most of them). They were so successful in their ideas that the Hart-Parr company was organized in Madison, Wisconsin on April 29, 1897. Until 1901 they operated their engine factory, perfected their valve-in-head engine design, as well as a cooling system employing oil as the cooling medium.15

Charles Hart left the company in 1917 and pursued business ventures on his own. He left Charles City and only returned upon the event of his death in 1937. The 1929 merger of Hart-Parr into the Oliver Farm Equipment Company brought about the Oliver Hart-Parr “Row Crop” tractor, an entirely new model with a unit frame design and vertical engine.

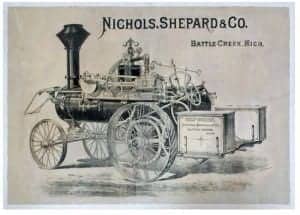

Nichols & Shepard Company

John Nichols started out as a blacksmith in Battle Creek, Michigan in the mid-1800s. He took in David Shepard as a partner very early in the history of the company. Hardly anything is known about the early history of the company; Nichols and Shepard probably relied on word-of-mouth as advertising for their products.

Around 1900 the company introduced their famous Red River Special line of threshers. Along with threshing machines, Nichols and Shepard designed and created a line of combines. After the merger of 1929, the Oliver company continued, for several years, to manufacture the Red River line of threshing machines and an entire line of combines and corn pickers first developed by Nichols and Shepard.

The Oliver Farm Equipment Company also merged with other farm equipment companies after the 1929 merger of the above mentioned companies.

Ann Arbor Machine Company

The Ann Arbor Machine Company had its foundation in 1882. They were known for, mainly, their production of hay presses (hay balers). The company began in Ann Arbor, Michigan and then moved in the 1920s to Shelbyville, Illinois. In 1943 a long-term business lease was extended to the company from the Oliver Farm Equipment Company. The Shelbyville plant was closed in 1970 and was absorbed into the Oliver factories at South Bend, Charles City, Iowa, and Brantford, Ontario, Canada.

Cleveland Tractor Company

Rollin H. White organized the Cleveland Tractor Company and incorporated it on January 29, 1916.17 Rollin and his brother were busy inventors and probably had invented a type of tractor as early as 1911. The Cleveland Motor Company manufactured tracked crawling tractors that used steel tracks instead of wheels.

The Cleveland Tractor Company’s plant in Cleveland, Ohio was acquired in 1944. They patented the name of their tractor, the Cletrac.

They produced a full range of crawlers with worldwide distribution. They patented a controlled differential steering, which is still in use by crawler and heavy machinery manufacturers today. The Oliver company continued to build Cletracs until 1962 when White Motor Corporation purchased the Oliver Farm Equipment Company.

Cockshutt Farm Equipment Company

James Cockshutt formed the Cockshutt Plow Company in 1877. It was incorporated in 1882 and the factory was located in Brantford, Ontario, Canada. The company first produced plows and other planting implements, however, they are best known for their tractors.

Their two-digit models of tractors were produced between 1946 and 1957.18 Tractor production at the Brantford plant ceased and all production turned to combine manufacturing for both Oliver and Cockshutt. The Cockshutt-built tractors were replaced with Oliver-built tractors painted the Cockshutt colors in Charles City, Iowa.

White Motors, the parent company of the Oliver Corporation, acquired Cockshutt in 1962. The Cockshutt name continued to be used until 1972, when they were slowly phased out by White. Cockshutt tractors were never built again. Instead, Oliver supplied them with tractors. At the same time Oliver-built combines were discontinued and Cockshutt became the combine builder for both companies. White Motors was the name of the company until 1969. By then it had acquired both Cockshutt and Minneapolis-Moline and reorganized as White Farm Equipment.

A.B. Farquhar Company

In 1889, A(rthur). B. Farquhar began building threshing machines and other farm machinery. 1920s Farquhar threshing machine Later, the company started the production of cultivators for farm use (especially potato harvesting equipment). Farquhar produced some steam engines early then moved onto the production of traction engines. In 1952 the A.B. Farquhar Company was sold to the Oliver Farm Equipment Company. When White Farm Equipment took over the Oliver Corporation, the Farquhar company was not included in the merger and ceased to exist.

The Last Days of the Oliver Farm Equipment Company

There was much more to the Oliver company than just production of farm implements. They built airplane fuselages for Boeing’s RB-47E Reconnaissance planes. In fact, the Battle Creek, Michigan plant had an entire aviation division set up for defense contracts. At that time, 37% of Oliver’s production was for defense contracts.19 The Charles City, Iowa plant was busy assembling transmissions for the 25-ton crane carriers for the U.S. Army Corp of Engineers. They also built and assembled the 106MM recoil-less rifle gun mounts for the Army. The Cleveland, Ohio plant built the MG-1 crawler for the Army, as well as, the M-47 tank final drives. They were also responsible for the turrets on the tanks. The Gilroy, California plant produced the 76MM guns for the Walker Bull-Dog tank, including many other gun tubes and parts. The Shelbyville, Ohio plant built the 155MM Howitzer gun parts.

The Oliver Corporation also built an industrial line of equipment that included industrial road graders, forklifts, road rollers, crawlers, and power units to be used by companies. By 1947, the Oliver Corporation employed 9,000 and business was continuing to grow. There were still members of James and J.D. Oliver’s family on the board of the Oliver Corporation. However, during the 1950s the company started to change.20

Oliver stock was being bought by people outside the company, which led to a corporate takeover. The majority of stockholders wanted to sell parts of the company off in order to make bigger profits (and to ‘line their pockets’). And that’s what a majority of stockholders agreed upon and the most successful parts of the Oliver company was bought by White Motor Company, making it a wholly owned subsidiary. At this time, all of the remaining Oliver family left the board of the Oliver Corporation. White Motors, now unimpeded, proceeded to keep what they wanted and sell off the rest.

Production of the White line of tractors and implements continued for several years. Oliver (or White) then began to buy up other companies and close plants to cut overhead expenses (and create more profits). This resulted in the closing of many of the oldest Oliver factories. Oliver tractors were manufactured until 1976 when the last Oliver 2255 rolled down the assembly line. The silver-colored White tractors had replaced the Oliver tractor. Throughout the many mergers and corporation maneuvering, nothing remains of the original Oliver company, which began its legacy in South Bend, Indiana. As of 2002, there isn’t even a White tractor company anymore. White Farm Equipment is owned by AGCO and the Oliver’s legacy must be left to be preserved by the many men and women who restore and show Oliver tractors and equipment.

- 1. Wendel, C.H. Oliver Hart-Parr. MBI: Wisconsin, 1993.

- 2. Ibid.

- 3. Ibid.

- 4. Schaefer, Sherry. Unpublished presentation, 2001.

- 5. Davis, H. Gail. Index to Oliver Historical Data: 1870-1929. Unpublished, 1955.

- 6. Ibid.

- 7. Ibid.

- 8. Oliver, James. Personal Journal. Unpublished.

- 9. Schaefer, Sherry. Unpublished presentation, 2001.

- 10. Ibid.

- 11. Ibid.

- 12. Ibid.

- 13. Ibid.

- 14. Wendel, C.H. Oliver Hart-Parr. MBI: Wisconsin, 1993.

- 15. Ibid.

- 16. Ibid.

- 17. Ibid.

- 18. Ibid.

- 19. Schaefer, Sherry. Unpublished presentation, 2001.

- 20. Ibid.